Top 10 Quality Control Problems in Wooden Toy Making (and How to Avoid Them)

- Share

- publisher

- Forestoy

- Issue Time

- Jun 25,2025

Summary

Learn the top 10 quality control issues in wooden toy production and how to avoid them. Perfect for new toy brands and eco-friendly manufacturers.

Top 10 Quality Control Problems in Wooden Toy Making (and How to Avoid Them)

Starting a wooden toy business? That’s awesome—and we’re cheering you on! But before you jump into production, let’s talk about something super important: quality control.

Even the smallest mistake in a toy can mean safety issues, bad reviews, or even product recalls. Nobody wants that. So let’s break down the top 10 quality problems we see in wooden toy making—especially for eco-friendly toys—and how to stop them before they start.

1. Paint That Chips or Peels

What’s the problem? Kids chew everything. If paint flakes off, it’s a health risk.

Why it happens:

Paint didn’t dry properly

Used low-quality or uncertified paint

Wood surface wasn’t sanded enough

How to fix it:

Always use certified child-safe paint (like EN71-3 or ASTM F963)

Sand the toy smooth before painting

Let paint fully dry and cure

2. Loose Small Parts

What’s the problem? Small pieces can fall off and be a choking hazard.

Why it happens:

Weak glue or poor assembly

Design isn’t suitable for young kids

How to fix it:

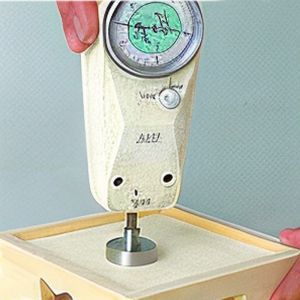

Do pull tests to make sure everything’s tight

Avoid small parts for toys meant for kids under 3

Double-check all small components

Small Parts Cylinder Test

Drop Test

Compression Test

3.Sharp Edges or Splinters

What’s the problem? Ouch! Splinters and rough corners hurt little hands.

Why it happens:

Rushed or uneven sanding

Cheap wood or bad cutting tools

How to fix it:

Sand in stages (from rough to fine grit)

Use quality wood and cutting tools

Train your team to feel for sharp edges

Sharp Piont Test

Torque Test

4.Off-Center Printing or Logos

What’s the problem? Logos or letters that are off-center look unprofessional.

Why it happens:

Printing machines not set up right

Wood moved during printing

How to fix it:

Use guides or templates for printing

Test alignment on the first piece of every batch

Do regular checks for accuracy

5. Pieces That Don’t Fit

What’s the problem? Puzzle pieces or blocks that don’t fit frustrate kids and parents.

Why it happens:

Cutting tools aren’t accurate

Wood got warped from moisture

How to fix it:

Use precise tools (like CNC or laser cutters)

Store wood in dry places to avoid warping

Always test fit before packing

6. Weak Joints or Glue Failures

What’s the problem? Toys fall apart too easily. Not good.

Why it happens:

Weak glue or not enough drying time

Didn’t clean the surface before gluing

How to fix it:

Use child-safe, strong glue

Let it fully dry before moving on

Safe and Durable Glue

Tension Test

7. Damaged or Wrong Packaging

What’s the problem? Torn boxes, missing labels, or incorrect age warnings cause trust issues.

Why it happens:

Poor packaging materials

Missed barcode or safety label checks

How to fix it:

Use sturdy, eco-friendly packaging

Double-check every label and barcode

Inspect packaging before shipping

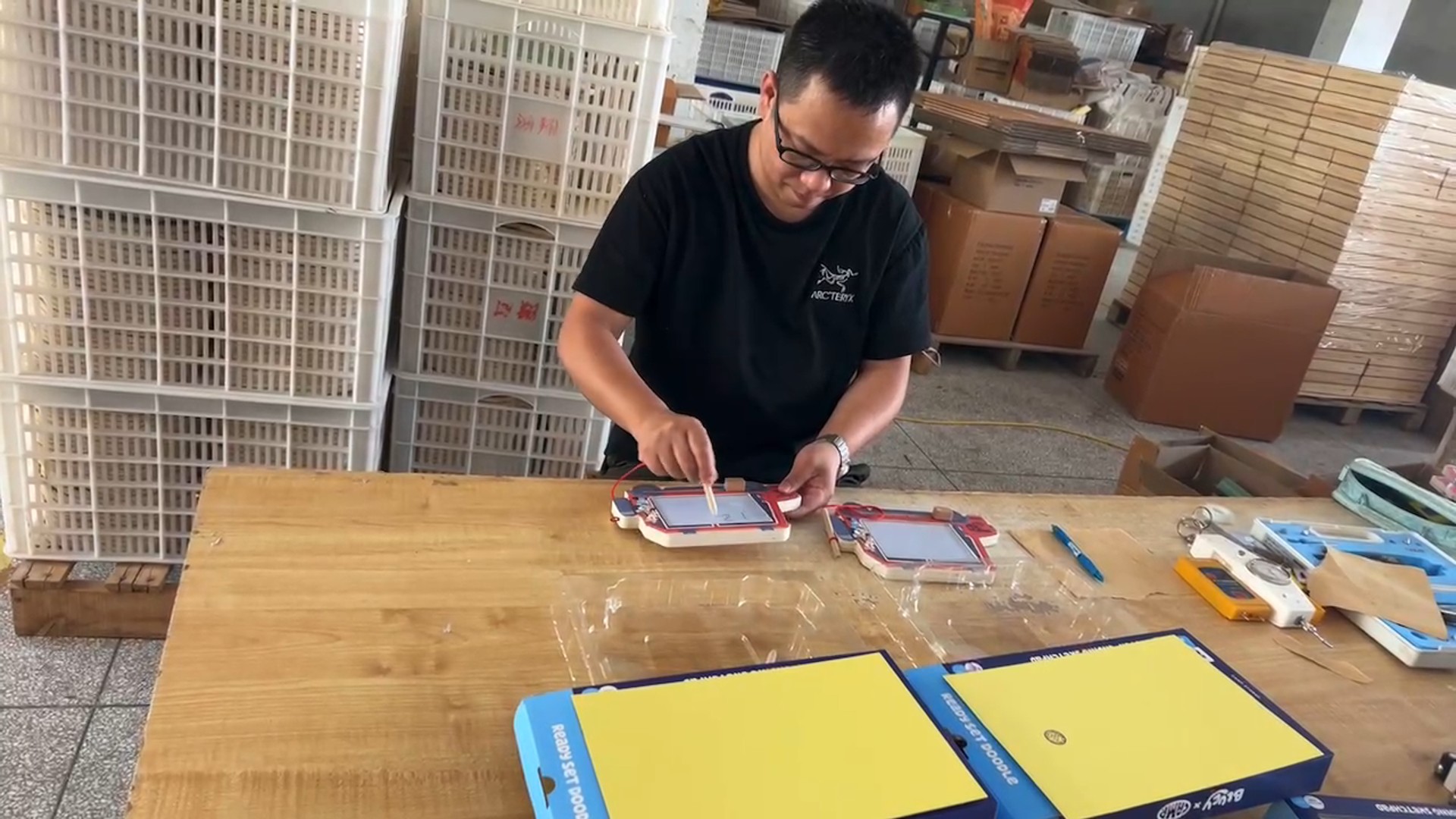

8. Dirt or Dust in Packaging

What’s the problem? Nobody wants to open a toy and find a hair or dust inside.

Why it happens:

No clean workspace

No pre-packing inspection

How to fix it:

Set up a clean area for assembly

Teach workers proper hygiene

Inspect each toy before packing

9. Not Meeting Safety Standards

What’s the problem? Failing tests like EN71 or ASTM F963 can lead to serious legal problems.

Why it happens:

Not keeping up with regulations

Skipping safety testing

How to fix it:

Work with a certified testing lab

Use only certified safe materials

Keep all your safety documents up to date

10. Color Doesn’t Match Across Batches

What’s the problem? Customers notice when two toys that should match… don’t.

Why it happens:

Paint wasn’t mixed the same

No color guide was used

How to fix it:

Stick to Pantone color codes

Use automated painting tools if possible

Set a clear color tolerance standard

Final Tips: Good Quality Starts EarlyTitle

You don’t need a huge team to make quality wooden toys—you just need a smart system. That means using good materials, working with the right partners, and checking your toys at every step.

At Forestoy, here’s how we do it:

🌿 We have FSC Certificate

🧰 We rely on skilled workers and multiple QC checks

📦 We use eco-friendly, safe packaging

✔️ And we follow all major toy safety standards (EN71, ASTM F963, ISO 8124)

Starting a wooden toy brand? Focus on quality now, and you’ll save time, money, and stress later. Want more tips? We’re here to help!